CONCORD UNITED PRODUCTS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to CONCORD UNITED PRODUCTS P.LTD.

High Precision Brass Wire Cnc Wire Edm Machines

| Technical Specifications | ||||

|---|---|---|---|---|

| ITEM | UNIT | SPECIFICATION | ||

| MACHINE. | ||||

| Size of work table (X, Y) | mm | 645 x 490 | ||

| Table travel (X, Y, Z axes) | mm | 400 x 300 x 220 | ||

| Dimension of work tank (LxWxH) | mm | 990 x 910 x 270 | ||

| Max. size of work piece (LxWxH) | mm | 850 x 700 x 215 | ||

| U, V axes travel | mm | 36 x 36 | ||

| Max. taper for 100mm thickness | ° | +/- 6 | ||

| Max. weight of work piece | Kg | 250 | ||

| Brass wire diameter | mm | Ø0.15 - 0.3, Standard 0.25 | ||

| Capacity of dielectric fluid / dielectric fluid | Ltr | 300 / D.M. Water | ||

| Filtration | Paper filtration | |||

| Capacity of resin | Ltr | 20 | ||

| Motors of X, Y, Z axes | AC servo motors | |||

| Motors of U, V axes | Stepper motors | |||

| Best surface finish * | µRa | 0.6 | ||

| Max. cutting speed* | mm²/min | 160 | ||

| Max. jog speed | mm/min | 1200 | ||

| Size of the machine (LxWxH) | mm | 1700 x 2550 x 2165 | ||

| Weight of the machine | Kg | 2500 | ||

| Floor space required (LxW) | mm | 2200 x 3300 | ||

| GENERATOR | ||||

| Display | 15" LCD monitor | |||

| Controlling axes | 5 axes, 4 axes simultaneously | |||

| Interppolation | Linear and circular | |||

| Min. input | mm | 0.001 | ||

| Max. input | mm | 9999.999 | ||

| Input | MDI / USB / Keyboard | |||

| Total power | KVA | 7 | ||

| Standard power supply | 415V / 3 Phase / 50 Hz | |||

| Max. working current | Amp | 25 | ||

| WORKING ENVIRONMENT. | ||||

| Standard room temperature for better accuracy | °C | 20 +/- 3 | ||

| Temperature allowed | °C | 15 - 30 | ||

| Humidity | % | 40 - 80 | ||

| Main Features | ||||

Note: Due to continuous engineering improvements, specifications are subject to change without prior notice * At Standard test conditions # Chasis |

||||

Cnc Wire Cut Machines

| Technical Specifications | ||||||

|---|---|---|---|---|---|---|

| Model -> | BM400C-C | BM500C-C | BM630D-C | BM800D-C | DK-7732C-C | DK-7740C-C |

| Table Travel X,Y Axis (mm) | 320 x 400 | 400 x 500 | 500 x 630 | 630 x 800 | 320 x 400 | 400 x 500 |

| Work Table Size L x W (mm) | 420 x 650 | 500 x 785 | 600 x 900 | 660 x 1100 | 420 x 650 | 500 x 800 |

| Maximum Work Piece Thickness (mm) | 300 | 300 | 500 | 500 | 300 | 300 |

| Maximum Taper / 100 mm Thickness |  3° (Standard) 3° (Standard) |

3° (Standard) 3° (Standard) |

3° (Standard) 3° (Standard) |

3° (Standard) 3° (Standard) |

||

| Maximum Work Piece Weight (kgs) | 400 | 500 | 800 | 3000 | 400 | 500 |

| Machine Weight (kgs) | 1800 | 2000 | 2300 | 4500 | 1600 | 1900 |

| Controller Specifications | ||||||

| Display | LCD Display | |||||

| Controller | BMW 5000 (High speed) - AC Servo control for BM series and Stepper motor control for DK series machines | |||||

| Control system | Japaneese YASKAWA servo control system for BM series machines. | |||||

| Max. Jog speed | 6000 mm/min. for BM series machines | |||||

| PC | Industrial PC # | |||||

| Axis Control | 4 - axes (X,Y,U,V) | |||||

| X, Y Axis Guide Ways | Precision linear motion guide ways for X, Y axis | |||||

| Wire tension mechanism | Double direction servo wire tension (Auto wire tension) | |||||

| Z axis | Motorized Z axis | |||||

| Resolution | 0.001 mm | |||||

| Wire frame | 'C' Type | |||||

| Wire Dia | 0.18mm (Std.), 0.15mm, 0.12mm (Optional) | |||||

| Interpolation | Linear and Circular | |||||

| Programming | Incremental | |||||

| Least Input Increment | 0.001 mm | |||||

| Least Command Input |  0.001mm 0.001mm |

|||||

| Data Input / Output System | USB Port , Regular Keyboard and Mouse; Can read AutoCAD .dxf format | |||||

| Input Power Supply | 3 Phase, 415 Volts, 50 Hz with Neutral and Earth | |||||

| Total Machine Load | 3.0 KVA | |||||

| Graphic Display | Graphic display of part showing wire position | |||||

| Processing and Data Entry | Dual Screen, New programs can be entered while cutting previous programme | |||||

| Auto Stop | Auto Shut-off at the end of program | |||||

| Dielectric Fluid | Soft water (D.M Water) + Gel | |||||

| Dielectric Tank Capacity | 55 Litres | |||||

| Standard Features | ||||||

Note: Due to continuous engineering improvements, specifications are subject to change without prior notice * At Standard test conditions # Chasis |

||||||

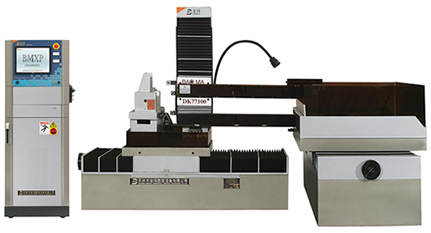

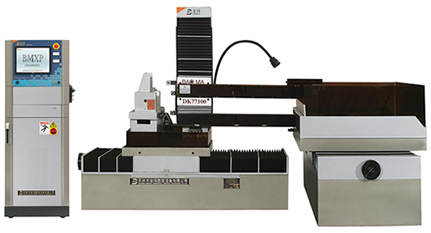

Cnc Wire Cut Edm Machines

| Technical Specifications | |||

|---|---|---|---|

| Model -> | DK-7763 | DK-7780 | DK-77100 |

| Table Travel X,Y Axis (mm) | 630 x 800 | 800 x 1000 | 1000 x 1200 |

| Work Table Size L x W (mm) | 660 x 1100 | 820 x 1400 | 1090 x 1600 |

| Maximum Work Piece Thickness (mm) | 500 | 500 | 500 |

| Maximum Taper / 100 mm Thickness |  3° (Standard) 3° (Standard) |

3° (Standard) 3° (Standard) |

3° (Standard) 3° (Standard) |

30° (Optional) 30° (Optional) |

30° (Optional) 30° (Optional) |

30° (Optional) 30° (Optional) |

|

| Maximum Work Piece Weight (kgs) | 3000 | 5000 | 5000 |

| Machine Weight (kgs) | 4500 | 6700 | 7000 |

| Controller Specifications | |||

| Display | LCD Display | ||

| Control System | CNC | ||

| PC | Industrial PC # | ||

| Axis Control | 4 - axes (X,Y,U,V) | ||

| X, Y Axis Guide Ways | Linear motion guide ways for X, Y axis | ||

| Resolution | 0.001 mm | ||

| Wire Dia | 0.18mm (Std.), 0.15mm, 0.12mm (Optional) | ||

| Interpolation | Linear and Circular | ||

| Programming | Incremental | ||

| Least Input Increment | 0.001 mm | ||

| Least Command Input |  0.001mm 0.001mm |

||

| Data Input / Output System | USB Port , Regular Keyboard and Mouse; Can read AutoCAD .dxf format | ||

| Input Power Supply | 3 Phase, 415 Volts, 50 Hz with Neutral and Earth | ||

| Total Machine Load | 1.5 KVA | ||

| Graphic Display | Graphic display of part showing wire position | ||

| Processing and Data Entry | Dual Screen, New programs can be entered while cutting previous programme | ||

| Auto Stop | Auto Shut-off at the end of program | ||

| Dielectric Fluid | Soft water (D.M Water) + Gel | ||

| Dielectric Tank Capacity | 55 Litres | ||

| Standard Features | |||

Note: Due to continuous engineering improvements, specifications are subject to change without prior notice * At Standard test conditions # Chasis |

|||

Edm Drilling Machines

| Technical Specifications | ||

|---|---|---|

| Model -> | DD703 | BMD703 (400) |

| Work Table Size L x W (mm) | 382x260 | 486x310 |

| Table Travel X,Y Axis (mm) | 300x200 | 400x300 |

| Z Axis Travel(mm) | 270+(220) | 300+(320) |

| Max. Drilling Depth(mm) | 0~220 | 0~300 |

| Max. Drilling Speed(mm2/min) | 30 | 30 |

| Max. Working Current(A) | 30 | 30 |

| Electrode Diameter(mm) | Ø0.3 ~ Ø3.0 | Ø0.2 ~ Ø3.0 |

| Load of Table(Kg) | 200 | 300 |

| Working Solution | Water | Water |

| Working Reservoir Capacity(L) | 25 | 30 |

| Power Supply | 415V/50Hz | 415V/50Hz |

| Max. Power Consumption(KVA) | 3.5 | 3.5 |

| Machine Dimensions(mm) | 1060x750x1700 | 1235x1025x1935 |

| Machine Weight(Kg) | 600 | 700 |

| Controller Type | Manual Z axis | Automatic Z axis |

| Digital Display | DROs for X, Y- axis | DRO for X, Y, Z - axis |

| Function of Setting Depth | No | Yes |

Mould Laser Welding Machines

| Technical Specifications | |

|---|---|

| Work Table Area | 130 x 100 x 300 mm |

| Max. Thickness of Job | 300 mm |

| Load Bearing Capacity | 200 Kgs |

| Laser Welding Depth | 0.1 - 3.2 mm |

| Wave Length | 1064 nm |

| Working Distance of Laser Weld | 100 - 200 mm |

| Laser | Ceramic condenser cavity (Imported from UK) |

| Viewing System | Telescopic microscope with cross wire |

| Amplification | 10 times (Optional 15X, 20X) |

| Laser Power (max) | 150 W |

| Single Pulse Energy (max) | 100 J |

| Range of Laser Spot Size | 0.2 - 2 mm |

| Pulse Width | 0.5 - 20 ms |

| Pulse Frequency | 0.1 - 15 Hz |

| Weld Area Protection System | Auto Synchronous argon gas protection for weld area |

| Welding Wires | Stainless steel, Hot die steel, P20 steel, HCHCr etc. |

| Input voltage | 380 V, AC, 50 Hz. |

| Max. Power | 8 KW |

| Max. Load Carrying Capacity | 200 Kgs |

| Cooling System | Water cooler (D. M. water with 12 LPM flow) |

| Standard Features | |

Note: Due to continuous engineering improvements, specifications are subject to change without prior notice * At Standard test conditions |

|

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.